The company attended the 2nd China New Energy Vehicle Test and Evaluation Technology Summit Forum in 2018 to discuss the application and development of the integrated platform technology for electric vehicle drive motor and generator system.

From July 20 to 21, 2018, the 2nd China New Energy Vehicle Test and Evaluation Technology Summit Forum was held in Pingshan, Shenzhen. The forum is under the guidance of Shenzhen Pingshan Science and Technology Innovation Service Department, and is jointly sponsored by Chongqing Vehicle Inspection and Research Institute Limited and Electric Vehicle Resource Network. Director of the testing center of Suzhou DSM Green Power Co., Ltd., shared the test and evaluation methods of the extender in his speech on the morning of 21.

Main contents of speech

The state's preferential policies for new energy vehicles are mainly electric vehicles, including pure electric vehicles, extended range electric vehicles and plug-in hybrid vehicles. Among them, pure electric vehicles (EVs) have gained popularity for their advantages of zero emission, low noise and simple structure. However, due to the limitation of power battery technology, it is difficult to achieve the mileage of traditional fuel vehicles, and the high cost of general EVs makes it difficult to develop and popularize them quickly. Plug-in hybrid electric vehicle uses mechanical hybrid structure, clutch, gearbox, etc. The structure is complex, and the battery energy is very small, only play an auxiliary drive and brake energy recovery role. Compared with the pure electric vehicle, the extended range electric vehicle increases the driving mileage and reduces the cost. Compared with plug-in hybrid vehicle, the working state of the extended range electric vehicle has nothing to do with the running state of the vehicle, and it can always work in the high efficiency area, which is more suitable for the urban road conditions with frequent load changes.

The configuration route of the power system of the extended range electric vehicle is mainly determined by three factors: the rated power of the extender (Pre), the rated power of the driving motor (Pmot) and the pure electric mileage (Rkm). Based on the different proportions of the three factors, different configuration routes of the range extender are formed.

Pre | Pmot | Rkm | Configuration | Notes |

1 | 1 | 50~80km | Mixing range extending | Comprehensive mileage is unlimited, oil is the main. |

1 | 1 | >150km | Electric power range extending | Comprehensive mileage is unlimited, electric is the main. |

<0.7 | 1 | 120~150km | Electric power range extending | >600km,Strong auxiliary range extension |

<0.5 | 1 | >100km | Auxiliary range extending | >450km,Light auxiliary range extension |

<0.3 | 1 | >100km | Replenish electricity range extending | >300km,Vehicle load assisted charging |

Note:

1. The power contrast coefficient is between Pre and PMOT;

2. The main

factors affecting the choice of different configuration are vehicle cost

and space limitation.

At present, it is difficult to test and evaluate the emission of the range extender according to the national standard, so it can only be tested according to the HEV emission standard of light vehicles. Power supply can support NEDC running in all operating conditions (therefore, the integrated range is limited after extended range), can not meet the HEV test standards.

In addition, because most of the range extender engine's main working conditions are completely out of line with the vehicle's working conditions, the vehicle's working conditions standard can not be used to test and evaluate the emission level of the range extender. The range extender’s control strategies vary widely, such as power follow, multi power platform, constant power and so on.

Emission test and evaluation of range extender

DSM has three emission test conditions: constant power (rated power) emission test-CPCT trial method (general evaluation), dual-power step test-T2P2 emission trial method (electric passenger vehicle, small and medium commercial vehicle), ESC test-MP6 trial method (heavy electric commercial vehicle).

CPCT trial method emission evaluation: when the engine is in the state of rated power, test the corresponding pollutant emission value of the range enhancer, record three times data, the average value as this emission value, unit g /(kWh). Comply with the emission limits specified in GB 17691-2005.

T2P2 trial method emission evaluation: The discharge tests were repeated three times as the corresponding pollutant emission value of the range enhancer in g /(100Km). The average emission limits should meet the emission limits given in GB18352.5-2013 after the corresponding deterioration.

MP6 trial method emission evaluation: When the engine is in the rated power state, the corresponding pollutant emission value of the range extender is tested, and three times data are recorded. The average value is taken as the emission value of this time, in g /(kWh). Comply with the emission limits specified in GB 17691-2005.

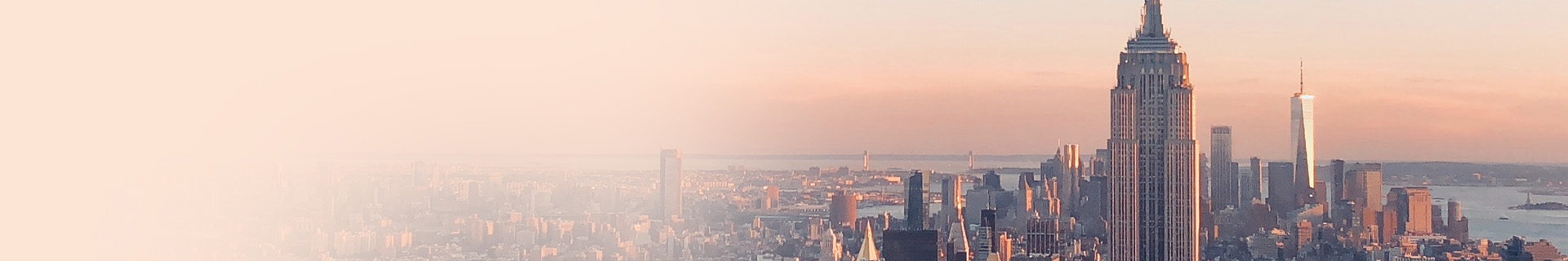

CPCT emission test method: Select the load box matching 100% load, and automatically run the range extended system (where: Pmax = RES rated power). The working condition and speed of the range extender are shown below. The speed of the vehicle is determined according to the steady speed of the vehicle.

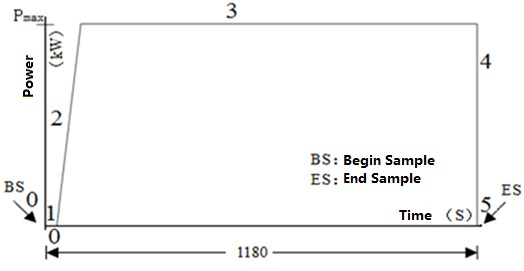

T2P2 emission test method: Referring to the speed state of NEDC (see GB18352-2013), half-power generation mode is adopted in urban (1 part) and rated-power double-step constant power generation mode is adopted in suburban (2 parts).

The working condition of the range extender and the corresponding speed change are shown below.

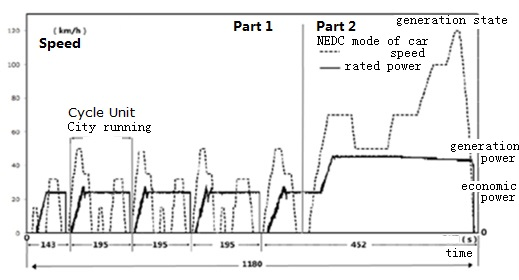

Mode number | RES working state | Weighting coefficient | Mode time/min |

| 1 | idle speed | 0.15 | 4 |

| 2 | economic power | 0.08 | 2 |

| 3 | rated power | 0.20 | 4 |

| 4 | economic power | 0.15 | 6 |

| 5 | rated power | 0.19 | 4 |

| 6 | peak power | 0.23 | 1 |

Noise measurement and evaluation of range extender

High power density (high engine speed) is the pursuit of the design of the range extender at the cost of increasing engine noise. When evaluating the performance index of the range extender, the noise level (dB) should be paid more attention to besides the rated power.

In terms of noise measurement and evaluation of range extender , DSM mainly used the following ways: running the extended range in the state of rated power continuous generation; measuring point 1.0m from the surface of the extended range; measuring the sound pressure level noise of 5 points around and above the extended range system; measuring value and background noise when measuring. When the difference is less than 4 dB, the measurement is invalid; the noise value between adjacent two measuring points should be less than 5 dB, otherwise the measurement point should be increased; according to the noise A weighted sound power level dB formula, the noise value is recorded.

In noise evaluation, it is divided into three grades: I-level noise - 70-75 dB; II-level noise - 75-85 dB (note: noise range of most extenders); III-level noise - 85-90 dB.

Test and evaluation of fuel consumption for range extender

The design pursuit of low speed and high power (noise reduction) may lead to increased fuel consumption, so when evaluating the performance indicators of the extender, in addition to the rated power and noise level (dB), it is necessary to evaluate the fuel consumption level. However, the 100 km fuel consumption level (L/100kM) of the vehicle is not directly related to the fuel consumption level (L/kWh) of the extended range generator.

In the fuel consumption test, DSM mainly uses the following ways: after the extender preheating, continuously generates electricity under the rated power condition, after the fuel consumption is stable, continuously records the fuel consumption delta m (L) and the generating voltage (U) and the generating current (I), the recording time is 1800 seconds. According to the formula, the total power generation and fuel consumption are calculated.