Most of the on-board extenders installed in the extended-formula pure-electric-drive electric vehicles use gasoline engines or diesel engines as power, while a few enterprises use natural gas or methanol engines as power to drive generators to generate direct current. The DC power generated by the extender is connected to the on-board power battery and the driving motor through the DC power bus of the electric vehicle. According to the energy management strategy, the DC power supplied to the driving motor or charged to the battery, or both can be carried out simultaneously. In principle, the working state of the extender is often independent of the vehicle running condition, or it uses a single constant power generation (T1) or two-stage constant power platform (T2) control strategies to achieve noise management, optimal power generation efficiency and minimum emissions.

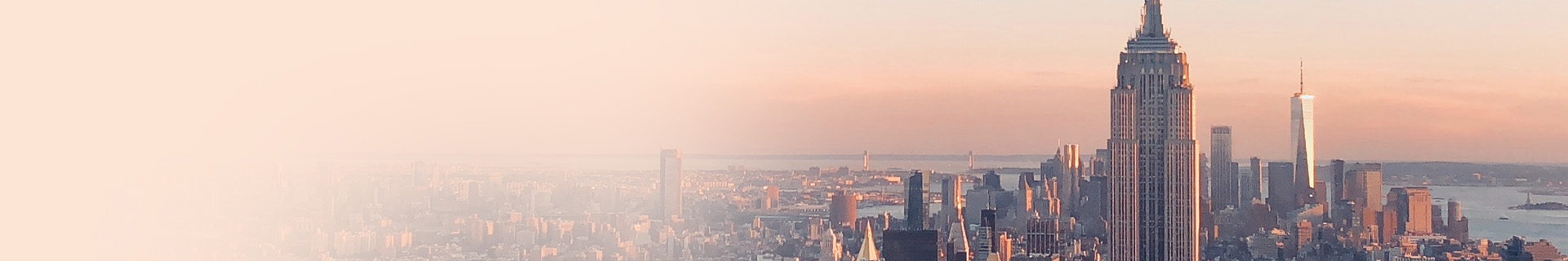

In addition to comparing the power density (kW / L) of the two extenders, the performance evaluation generally includes generation noise, generation fuel efficiency (L / kWh) and emission indicators.

The total exhaust emissions of the extender are affected by the performance of the engine and the efficiency of the generator system respectively, and also by the performance matching optimization between the engine and the generator. It is a system engineering problem.

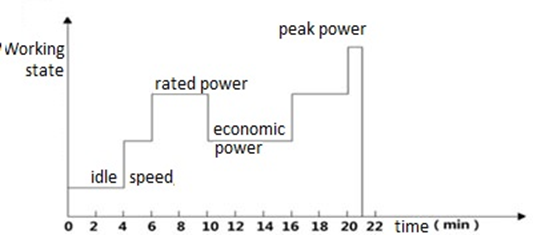

Fig. 1. Fuel consumption characteristics of range extender

Different control strategies for the range extender system also affect emissions and fuel efficiency. Therefore, the evaluation of the exhaust emission performance of the extender needs an independent evaluation and test standard, which can reflect the influence of engine and generator performance on the exhaust emission respectively, and also reflect the optimization effect of the matching of the two, excluding the influence of different control strategies (most of the control strategies are adjusted and optimized by the vehicle factory in the vehicle integration process).

1. Terminology and definition

GB/T 2900.11, QC/T 743-2006 and the following terms and definitions are applicable to this standard.

1.1 Range Extender

A vehicle-borne DC power generation system, powered by an engine (fuel, gas or alcohol ether) and powered by a generator, is designed to rectify and control the output DC power through a controller. The output current or voltage can be continuously adjusted, mainly working at constant power and speed conditions.

1.2 Energy conversion rate of range extender

The fuel consumed per kilowatt hour of a range extender at rated speed at rated power is L/kWh.

1.3 Rated Power

The range extender rated power output of a generator at rated speed.

1.4 Generation rate

Range extender Generation rate = Range extender actual generation power / Range extender rated power

2. Emission

2.1 Requirement

2.1.1 Range extender state and installation requirements

a) The range extender for emission measurement must be a range extender that meets the inspection requirements.

b) The engine ECU and fuel tank should be consistent with the factory status, and the fuel tank cover should comply with the requirements of GB18352.5-2013.

2.1.2 Related measures and requirements

c) Exhaust devices such as silencers and catalytic converters must be consistent with the qualified products of the factory.

d) The necessary running in should be carried out before the emission measurement starts, and the cumulative running in time should not exceed 1 hours.

2.2 Experimental auxiliary equipment

In emission testing, a load box (adjustable electronically or resistively) should be equipped to match the power generated by the extender. The load size of the load box should be changed during the operation to meet the requirements of different power generation rates during the testing process.

2.3 Test method

Range extender emission test is divided into three methods: constant power constant speed test (ordinary commercial pure electric drive vehicle), variable power test (pure electric drive passenger vehicle) and ESC working condition test (heavy pure electric drive commercial vehicle).

2.3.1 Constant power method test - CPCT test method

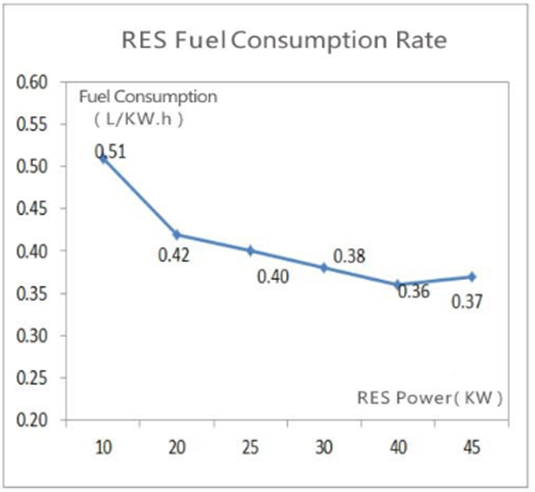

CPCT test, select 100% load matching load box, automatically run the system, the test process is executed according to figure 2.

Fig. 2 CPCT emission test cycle

Among them: Pmax= range extender rated power, speed determined according to vehicle design document.

2.3.2 dual-power step test - T2P2 test method

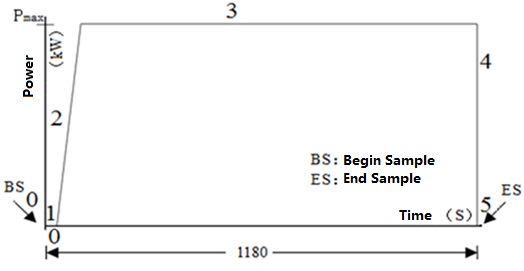

Referring to GB / T 19755 - 2016 NEDC operating mode (two operating modes - abbreviated as P2), the test method of the power generation condition (abbreviated as T2) of the double step range extender - T2 P2 testing method is determined, and the cycle test is carried out according to the requirements of Figure 3.

Among them: the actual power generation of the range extender in the test process = power generation rate (%, figure 3 solid line) * range extender rated power

Fig. 3 Emission test cycle of T2P2 test method

2.3.3 ESC mode test - MP6 test method

The engine is preheated by a range extender. The preprocessing adopts sequential cyclic operation of idling speed 1 min, half power 5 min, rated power 5 min and peak power 1 min. The accumulated time is not less than 1 h. The test extender should operate on the dynamometer according to the 6 working cycle listed in Table 1 and Figure 4:

Table 1

Mode number | RES working state | Weighting coefficient | Mode time/min |

idle speed | 0.15 | 4 | |

economic power | 0.08 | 2 | |

rated power | 0.20 | 4 | |

economic power | 0.15 | 6 | |

rated power | 0.19 | 4 | |

peak power | 0.23 | 1 |

Fig. 4 Emission test cycle of MP6 test method

2.3.4 Test times and limits

The emission tests of CPCT constant power method and MP6 working condition method were repeated three (3) times as the corresponding pollutant emission value of the range extender. The unit is g/ (kWh). The average emission limits should meet the emission limits specified in GB17691-2005.

The emission test of NEDC working condition method was repeated three (3) times. As the corresponding pollutant emission value of the range extender, the unit was g/100Km. The average emission limits should meet the emission limits given in GB18352.5-2013 and the degradation system coefficients should meet the requirements of GB18352.5-2013. If the sum of emissions of each pollutant or two pollutants is not more than 0.70L (i.e. V1 < 0.70L, less than 0.7 times the emission limit), only one test can be conducted.

3. Power generation efficiency

3.1 Calculation of power output of range extender

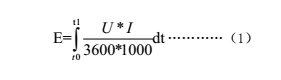

The DC voltage and current at the output of the generator controller are measured in real time during the test of the range extender. The generator power of range extender is calculated according to formula (1).

In the form:

E -- the power output of range extender. The unit is kilowatt hour (kWh).

t0 - the start time of the test is in seconds (s).

t1 - the end time of the test is in seconds (s).

U - the output voltage of the generator controller is V volt.

I - the output current of the generator controller is Ampere (A).

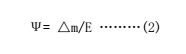

3.2 Calculation of energy conversion rate of range extender

The energy conversion rate of the range extender is calculated by pressing (2).

In the form:

Ψ——Energy conversion rate of range extender. The unit is litre per kilowatt hour (L/kWh).

△m——Fuel consumption of fuel engine during the experiment. The unit is litre (L).

3.3 Test method

According to the technical document of the range extender, the range generator is selected to generate electricity at rated power and continuously tested for 1800 seconds.

4.Noise

The range extender noise measurement should refer to GB1496-1979 requirements.

4.1 Measuring instrument

Noise measurement instrument error: no more than + 2dB. Before the measurement begins, the instrument is calibrated according to the noise measuring instrument. The instrument can be used after the calibration is accurate. The A sound level and F gear are selected for the measurement.

4.2 Environmental requirements

The noise test was conducted in the silencer room. The ambient temperature is -10 ℃ ~45 ℃, humidity 15%~95%RH.

4.3 Test method

1) working condition of range extender: rated power generation (constant power).

2) the measurement is invalid when the measured value is different from the background noise below 4dB.

3) the noise level between adjacent two measuring points should be within 5dB, otherwise the measurement points should be increased.

4) the measuring point must be at 1m from the surface of the motor.

5) According to the formula of noise A weighted sound power level dB (A), the noise value should not exceed the limit required by the corresponding technical documents.